Rotolining

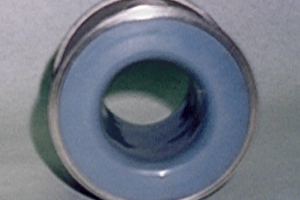

Rotolining is a process that allows a chemically modified polyethylene to form a bond with metals or other resins. The bonded plastic can be used to line metal vessels, tanks, pipes or other components for corrosion protection and chemical resistance.

Rotolining is a process that allows a chemically modified polyethylene to form a bond with metals or other resins. The bonded plastic can be used to line metal vessels, tanks, pipes or other components for corrosion protection and chemical resistance.

The choice of which plastic to use is based on the chemical resistance properties that are required of the final part. We work with many materials and several other resins to meet the specific rotolining characteristics for your application.

Rotolining Benefits:

- Protection from acids, alkalis, oxidizers, solvents

- Resistant to permeation

- Maintains purity at parts per billion levels (fluoropolymers)

- More economical than alloys or glass lined vessels

- More durable than thermoset resins

- Greater strength than FRP when bonded to steel

- Can be shop or field installed

- Seamless surface finish

- Lining thickness from 100 to 250 mils

- Easier to line complex shapes

Rotolining Applications:

– Pipe spools, Elbows and Adapters

– Small reactors

– Filter Housings

– Small Storage Vessels

| Rotolining Materials | Trade Name | Min. Thickness (in.) | Max Thickness (in.) |

| ETFE | Tefzel® | 0.10 | 0.25 |

| ECTFE | Halar® | 0.10 | 0.25 |

| PVDF | Kynar® | 0.10 | 0.25 |

Tefzel is a trademark of Chemours. Halar is a trademark of Solvay Plastics. Kynar is a trademark of Arkema.